Knives a-go-go

/A joint post by T and Em-i-lis As many chefs, both professional and home, already know, sharp knives are essential kitchen tools. Early on in our marriage, Tom asked for great knives for his birthday; his mother gave him three or four terrific Japanese Globals (the steel used is harder) and initially we were thrilled, but over time we became less impressed. The Globals-specific sharpener sold at Sur la Table seemed ineffectual and because it was easier to sharpen our German Wusthofs, we used them more and felt more positively about them.

If you are or become interested in knife sharpening and skills, it's easy to go down the internet rabbit hole where you'll find multiple forums of people vigorously debating the virtues of one chemical blend of steel to another or discussing exotic sharpening stones. But you needn't obsess (unless you want to); simply knowing just the basics can dramatically improve the effectiveness of your knives. Here are some tips...

Tip #1: Buy quality knives. If you've got good chef's and paring knives (even just one of each), probably 90% of your needs will be met, and with care they'll last decades. If you plan to cook regularly, splurge on these. You won't regret it. If you've never used a larger knife like a chef's knife it may feel unwieldy at first. For this reason, I thought I'd like a short chef's knife -like a 6" one- but am now glad I got the more standard-sized 8". (In fact, I'm thinking about getting a 10"). You'll get used to the larger knife with a little practice and it is much more versatile in my opinion. One piece of advice: virtually all of the good brands now also sell lower-end models made of machine-stamped, lesser-quality steel. In contrast, their better counterparts tend to be made in a forged process in which the (better-quality) steel thickens as it approaches the attached handle. We often prefer the weight of this kind of knife too. That said, Victorinox makes some stamped-metal knives that are inexpensive yet get very good reviews.

One good source of terrific knives at good prices is Cutlery and More, an online store.

Tip #2: Hone your knives with a good steel. Honing is not the same as sharpening; rather, it's something you can/should do each time you use each knife and involves running the blade over a sharpening steel or ceramic rod a few times. What's really happening, as I understand it, is the straightening out of the knife's microscopic edge which may have begun to curl over. The following video provides a very detailed tutorial. For harder steel like that used in Japanese knives, you'll want to get a ceramic rod though the ceramic can be used for German style knives (which use a softer steel blend), too.

http://www.youtube.com/watch?v=MUdrRE7W0b4

Tip #3: Cut on a good board. Don't use your nice knives when cutting on surfaces like glass or granite as doing so will dull them very quickly. Our favorite surface is a maple butcher block. Some of these boards are crafted in such a way that at a microscopic level the wood fibers resemble a very dense shag carpet. This makes a sturdy cutting surface that is also very gentle on the knife; the tip of the blade actually slides between the fibers to some degree when slicing.

If you're already up to speed there, it's time to move into the realm of sharpening:

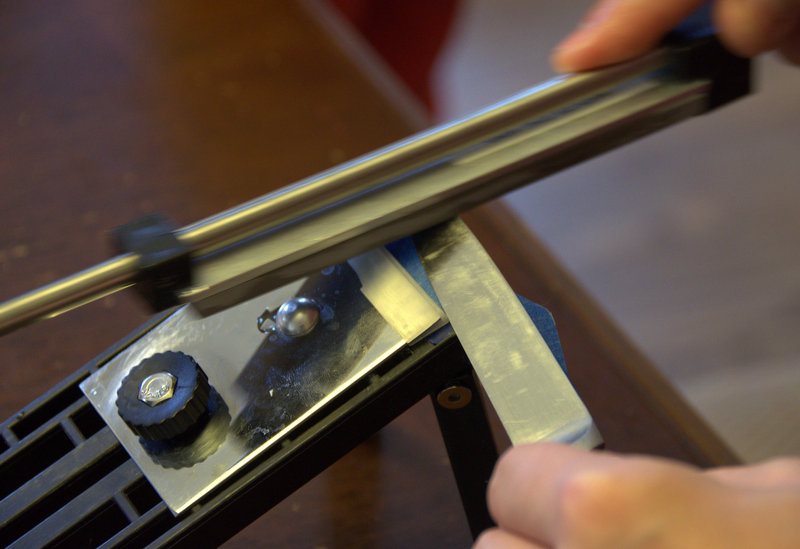

When you sharpen a knife, you are actually removing a layer of metal from each side of the beveled tip to make a brand new edge. As such, this is not something you want to do every day since over time it will actually grind down your knife (and it isn't necessary). The hardest part of sharpening knives is getting the angle just right. Knives are designed to be sharpened at a specific angle -- usually 18-20 degrees for German-style steel and 15 degrees for harder Japanese steel. If your angle is too acute, the blade will dull quickly; too wide and it won't be as sharp. You want this angle to be constant while sharpening.

Sharpening options:

One option is to get a manual sharpener with a fixed angle. We had one like this which for years worked pretty well. To some degree though, it hones rather than sharpens so it never returned our knife blades to their best edge.

You can also purchase motorized sharpeners, some of which get good reviews, but you'll need to take caution not to grind away too much material so carefully read the reviews and instructions. For example, some rave about using diamond as the sharpener. This sounds great and is certainly an effective means of grinding steel, but many experts suggest it is too harsh.

The "real" way to sharpen is with a sharpening stone. These stones, whether natural or synthetic, are made by suspending abrasives in another material that is water soluble. As you sharpen with these stones, a small amount of the stone wears away creating an abrasive slurry that simultaneously grinds the blade's edge uniformly and washes away the excess steel. The very best sharpening stones are quite expensive, and I was nervous about how I would maintain the proper sharpening angle. Ultimately, after a good deal of research I bought this.

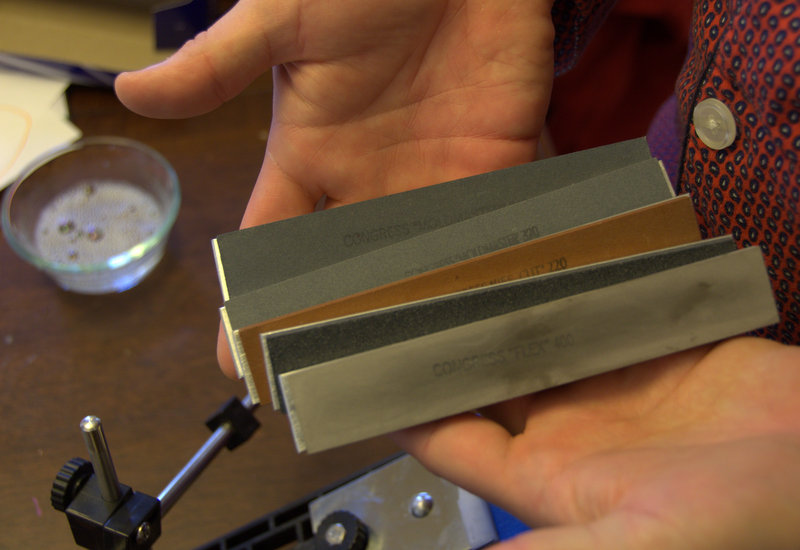

This is a generic knockoff of the Edge Pro Apex knife sharpening system. The Edge Pro gets great reviews but is also pricey (roughly $200), so some enterprising Chinese manufacturer started making and selling these on eBay. Lovingly known on knife sharpening forums as the Edge Faux, this system comes with very low-quality sharpening stones. But, thanks to some other hard-core users (not me!), I found I could source really great synthetic stones from companies which make them for commercial use. I got mine from Congress Tools. There, you can get a variety of stones for a reasonable cost.

To sharpen a really dull knife, you'll want to start with a coarser-grit, harsher abrasive like the Congress "MoldMaster" series and then progress to finer-grit, less abrasive stones like the Congress "Res-Cut" and "Flex" series in order to finish the edge. To make it easier to mount my stones on the Edge Faux, I bought a 1" thick piece of aluminum sheet metal on which I glued each.

You use this sharpener by setting the angle and then moving the stone along the edge of the blade. Doing this is difficult for me to describe well in text, so if you want to see how sharpening in action, watch this video from EdgePro. It's actually quite simple to learn. http://www.youtube.com/watch?v=CY6DJ0PQxyA

The result is amazing. All our knives cut like I never remember them cutting before, particularly the Globals for which I have found a new love . Hard-to-slice foods like overripe tomatoes can be cut paper-thin without crushing them.

If you want a terrific reference book regarding knives and sharpening, check out An Edge in the Kitchen.

Of course, if this is all too much of a pain, do yourself a favor and get your knives sharpened by a pro and then keep them in good shape by honing regularly.